Copper Busbar Current Carrying Capacity

1500 ampere copper busbars within a power distribution rack for a large building. U-25s bottoming plant was actually operated under contract.

What Is The Current Carrying Capacity Of Cu Bus Bars Quora

208V single phase can be achieved between high leg delta orange color and neutral.

. A very approximate method of estimating the current carrying capacity of a copper busbar. The equivalent current carrying capacity should be used for selecting the conductor size for thermal withstand. The bus bar 100mm x25mm x15mm is suitable for incomer current 1002515124500A.

16 mm 2 copper or 25 mm 2 aluminium. A 6 mm 2 cable with copper conductors has a current-carrying capacity of 40 A and hence is suitable if harmonics are not present in the circuit. They are mainly used in the high current junction like breaker joint male female contact operation frequency converters etc.

Wiring is subject to safety standards for design and installation. The manufacturer has consider the Busbar size is 10012 mm1200 sqmmcopper Bus single. 11 KV SINGLE CORE ALCOPPER CONDXLPE INSULATED CABLES As per IS7098 Part-I Cross-sectional area Sq MM UN-ARMOURED CABLE Overall Diameter mm Normal Current Rating in Amps Short Circuit Current Rating for 1Secduration in K.

T is the total time of duty cycle. X 2 in and whatever length is needed for all the connections. In 1971 the natural-gas fired U-25 plant was completed near Moscow with a designed capacity of 25 megawatts.

Electrical busbar systems sometimes simply referred to as busbar systems are a modular approach to electrical wiring where instead of a standard cable wiring to every single electrical device the electrical devices are mounted onto an adapter which is directly fitted to a current carrying busbarThis modular approach is used in distribution boards automation panels and. 11kv Two 11kv incomer feeder cubicle Four 11kv load feeder cubicle. The material around these bends and holes becomes work hardened and the increased resistance will skew the estimations provided by the ampacity chart.

A 400-ampere feeder made up of four 600 kcmil copper conductors and one size 3 AWG copper equipment grounding conductor is installed to supply a separate building. Busbar bushing type where there is a piece of busbar normally made of copper already embedded in resin. Welded joints not very safe Welded joints are made by butting the ends of the bars and weldingThey are compact and have the advantage that the current-carrying capacity is unimpaired as the joint is effectively a continuous copper conductor.

In any case the number of primary turns in this case is always 1. For example if we select busbar to be of the size 20mm x10mm with a length of 24m Wöhner item code -01624 and if we select air temperature of 35C and busbar temperature of 85C we will get the current carrying capacity 652A. Aluminium and copper are the most available material in the earth but the copper conductor carries 40 extra current than the aluminium conductor.

The second option is to use a busbar as the common grounding electrode conductor. Solar panels use sunlight as a source of energy to generate direct current electricityA collection of PV modules is called a PV panel and a system of PV panels is called an array. In indoor substation copper or Aluminum bar is used as a bus bar.

The following tutorial shows how to wire a 208V single phase breaker fed up by a high leg delta busbar for residential and commercial uses. Go back to Factors affecting cable selection. In case of aluminium bus bar the current carrying capacity is 08max.

XLPE Insulated Armored Unarmored Cables. The current-carrying capacity of a busbar is usually determined by the maximum temperature at which the bar is permitted to operate as defined by national and international standards such as British Standard BS 159 American Standard ANSI C3720 etc. Three-phase circuits of csa.

Electricity is the set of physical phenomena associated with the presence and motion of matter that has a property of electric chargeElectricity is related to magnetism both being part of the phenomenon of electromagnetism as described by Maxwells equationsVarious common phenomena are related to electricity including lightning static electricity electric heating. The only grounding electrode present is a metal in-ground support structure for the building. Go back to Methods.

This comes into play as the metal is hardened by rolling stamping bending or hole punching. Copper busbar in an LT Panel. By 1994 Russia had developed and operated the coal-operated facility U-25 at the High-Temperature Institute of the Russian Academy of Science in Moscow.

Aluminium and Copper Current Carrying Capacity Calculation Chart in Sqmm. In electric power distribution a busbar. E is the voltage of the cable.

A hollow section also has higher stiffness than a solid rod of equivalent current-carrying capacity which allows a greater span between busbar supports in outdoor electrical switchyards. The selection of cable size is based upon the following. Busbar bushing type.

T is the time period of constant current. By 1974 it delivered 6 megawatts of power. Estimated 6MVA capacity operating voltage.

So the bus bar 100x25x15 is suitable for 1002515083000A incomer current. Standard Bus-bar Cable Standard Carbon Dioxide Carrier Chiller Celling Fan Wiring Circuit Breaker Circuit Protective Conductor Current Carrying capacity DC 23 Wire System DC System ECC Earth Fault Relay Earth Leakage Relay Electric Bill Electrical Cord Electrical Fire. In this case we have connected a hand dryer 208V 15A to a single pole breaker.

The harder the copper or aluminum etc the worse it becomes at carrying a current. Allowable wire and cable types and sizes are specified according to the circuit operating voltage and electric current capability with further restrictions on the. If the load is evenly split across the two directions the current in each direction is half of the total allowing the use of wire with half the current-carrying capacity.

In this case the terminals of the primary winding are the ends of the busbar whereas the ends of the secondary winding are taken to external terminals. In practice it is impossible to ensure the load does split evenly so regulations require a thicker wire of at least 23 the current capacity of the fuse or circuit breaker. A solar cell panel solar electric panel photo-voltaic PV module or solar panel is an assembly of photo-voltaic cells mounted in a framework for installation.

By giving these inputs we can get the current carrying capacity of the Busbar. What will be the magnitude of current of one 1600 KVA 3 phase Transformer at its LV winding side. What is the Current density of the Copper and is the Busbar size sufficient for that Transformer.

Refer screen shot 3. The bus bar is required to be sized a minimum of 6 mm 50 mm ¼ in. Copper busbar current carrying capacity 12 Busbar width Thickness in Amps.

Figure 4 A soldered joint. Electrical wiring is an electrical installation of cabling and associated devices such as switches distribution boards sockets and light fittings in a structure. Highly specialized for design of LVMV switchgears and LV high power busbar trunking.

Amps Aluminums Conductor Copper Conductor Aluminums. Hence the total current carrying capacity of the copper 1200 Amps of 100mm width and 10 mm thickness. But the cost to sqmm points of view ie the cost of 3 core 35sqmm aluminium cable has Rs 16per sq.

The HVDC Inter-Island link is a 610 km 380 mi long 1200 MW high-voltage direct current HVDC transmission system connecting the electricity networks of the North Island and South Island of New Zealand together. If the busbar is carrying AC current. It is commonly referred to as the Cook Strait cable in the media and in press releases although the link is much longer than its Cook Strait section.

In case of copper bus bar the current carrying capacity is 12max. Meter and copper conductor has Rs 30 per sqmm. What is the minimum size grounding electrode conductor required for the building served.

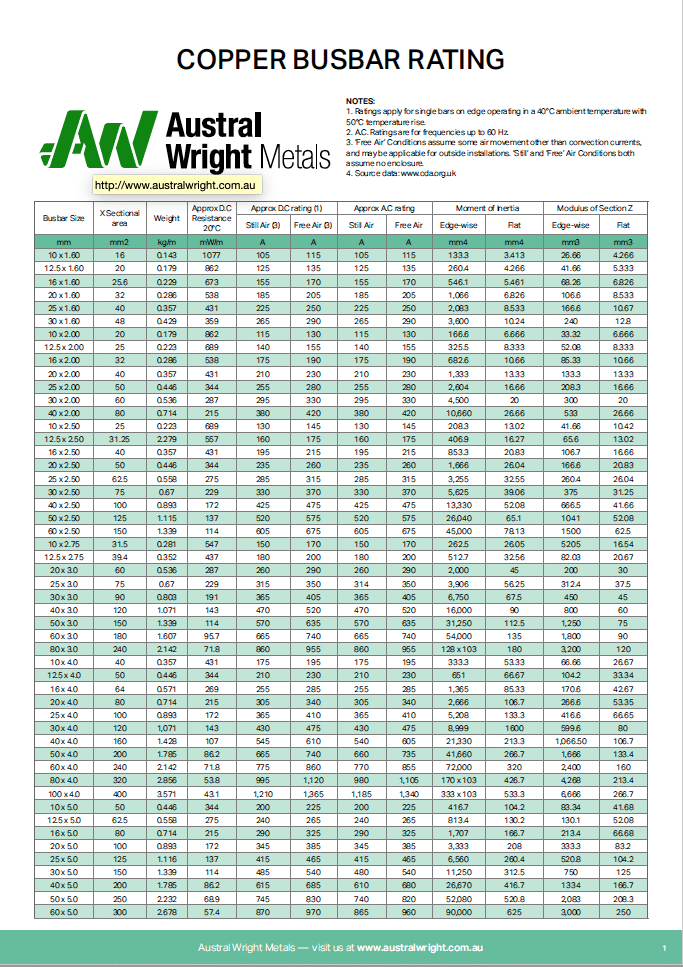

The dimensions stated in this table are based on bare copper at ambient temperature of 40 C maximum permissible temperature rise of 50 C operating at 50 Hz. Arrays of a photovoltaic system supply solar.

Copper Busbar Rating Austral Wright Metals

Complete Current Busbar Table Rectangular

Busbar Size Calculation Formula Aluminium And Copper Examples Wira Electrical

No comments for "Copper Busbar Current Carrying Capacity"

Post a Comment